Essential Considerations for Selecting the Best Engine for Your Requirements

In the realm of choosing the optimal engine to satisfy your needs, several critical elements need precise factor to consider to guarantee optimum efficiency and performance. From the nuanced balance in between power and efficiency to the often-overlooked facets of maintenance and service demands, each element plays a critical function in determining one of the most suitable engine for your certain needs. As the complexity of engine innovations proceeds to evolve, discerning the most suitable alternative necessitates a deep understanding of the interaction in between numerous considerations. By exploring the complex web of elements that underpin this decision-making procedure, a clearer path emerges towards selecting an engine that not only meets however surpasses your expectations.

Power and Efficiency

When examining engines for optimal efficiency, it is essential to prioritize both power outcome and effectiveness. Power output gauges the capacity of an engine to generate energy, which directly impacts its performance. A high power outcome is important for demanding jobs such as sturdy applications or high-speed demands. It makes certain that the engine can take care of the work effectively and effectively. However, power alone is not sufficient; efficiency plays a considerable role in establishing the total efficiency of an engine. Efficiency describes how well the engine converts gas into usable power. A much more efficient engine will certainly deliver far better mileage, reduced emissions, and decreased operating expense. Striking the appropriate balance between power outcome and efficiency is crucial to picking an engine that meets your certain demands. When making this choice, it is essential to think about factors such as the meant usage of the engine, environmental influence, and long-term price effects. By meticulously evaluating both power and performance, you can pick an engine that supplies optimal performance and meets your requirements properly.

Gas Efficiency and Economy

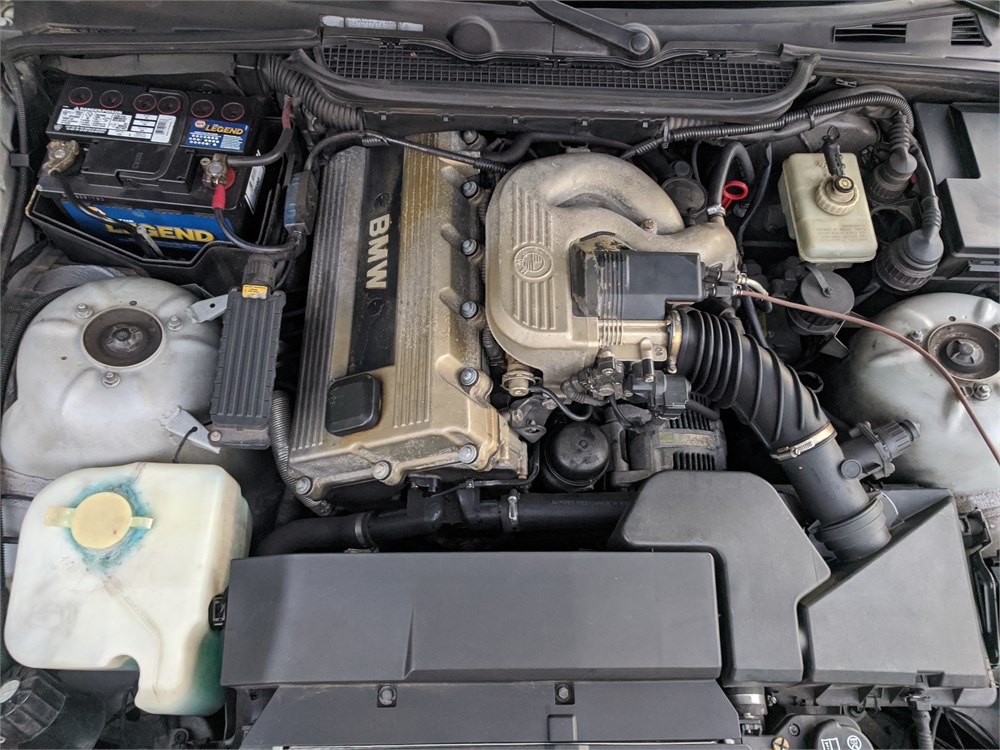

In the world of engine choice, the factor to consider of gas performance and economic situation holds paramount importance. Gas effectiveness describes the engine's capacity to convert gas into energy with very little waste, straight affecting operating costs and ecological sustainability. bmw 318ti. When picking an engine, assessing its fuel economic climate is essential to figure out long-term financial savings and environmental influence. Engines with higher fuel effectiveness not only lower gas expenses however also lower carbon emissions, adding to a greener procedure.

Compatibility and Application

Considering the gas performance and economic climate of an engine, the next critical element to address is its compatibility and application within certain operational contexts. Compatibility refers to exactly how well the engine integrates with the overall system or devices it powers. It includes variables such as physical dimensions, installing alternatives, electric user interfaces, and control systems. Making sure compatibility is necessary to prevent concerns such as getting too hot, vibrations, or power discrepancies (bmw 318ti).

Moreover, the application of the engine is just as important. Different engines are made for certain purposes, whether it be industrial equipment, aquatic vessels, autos, or power generators. Recognizing the desired application permits the option of an engine that can deliver the needed power result, torque, and functional attributes. A high-revving engine created for performance autos would not be appropriate for durable building and construction tools that calls for high torque at reduced rates.

Maintenance and Service Needs

Upkeep and service demands play a critical duty in ensuring the durability and optimum performance of an engine. Routine upkeep is essential to protect against failures, prolong the life expectancy of the engine, and maintain its effectiveness. When picking an engine, it is necessary to think about the manufacturer's suggested upkeep timetable and the schedule of solution centers or certified technicians.

Aspects such as the regularity of oil adjustments, filter substitutes, and total examinations can substantially affect the engine's efficiency. Some engines may need even more constant maintenance based on their design and use, while others might have longer intervals between maintenance checks. It is important to stick to these service requirements to prevent costly fixings and unanticipated downtime.

Price and Budget Factors To Consider

When choosing an engine for a certain application,Spending plan restrictions commonly play a substantial function in the decision-making procedure. When thinking about the price and spending plan implications of choosing an engine, it is important to assess not just the preliminary acquisition rate but additionally the long-term costs related to upkeep, gas consumption, and prospective upgrades or repairs. It is vital to strike a balance in between the in advance expense of the engine and its general lifecycle costs to make sure that the picked engine continues to be monetarily sustainable throughout its operational life expectancy.

Factors such as gas toughness, efficiency, and reliability can straight influence the total cost of learn the facts here now possession of an engine. While an extra costly engine might have greater in advance costs, it can possibly cause lower upkeep and fuel expenditures in time, thus supplying better value over time. In addition, considering the schedule and price of extra parts, as well as the simplicity of maintenance and service, can help protect against unforeseen monetary stress in the future. By very carefully examining these price and spending plan considerations, you can make an enlightened choice that straightens with your functional demands and economic restraints.

Verdict

Gas efficiency refers to the engine's capacity to convert gas right into power with minimal waste, directly influencing operating costs and ecological sustainability.Variables affecting gas performance consist of engine article source design, burning efficiency, and total efficiency optimization. In addition, picking the appropriate gas kind and quality as advised by the engine maker can even more improve performance and prolong engine lifespan.

Engines with good service attributes and easily offered components can reduce maintenance costs and minimize the time the engine is out of operation - bmw 318ti. It is essential to strike an equilibrium between the upfront expense of the engine and its general lifecycle expenses to guarantee that the selected engine remains monetarily lasting throughout its operational lifespan